In today’s fast-paced, technology-driven world, maintaining the efficiency and reliability of electronic systems is essential. Electromagnetic interference EMI can disrupt sensitive devices and compromise overall performance. Trusted EMI shielded enclosure designs provide the protection necessary to ensure optimal functionality, safety, and consistency across diverse applications worldwide.

Enhancing System Integrity Through Effective Shielding

Electromagnetic interference can stem from multiple sources, including wireless devices, industrial equipment, and power systems. To counter these disruptions, EMI sheet metal enclosure design create a controlled environment that blocks external noise and prevents signal leakage.

- Reliable Protection: Effectively contains and isolates sensitive electronics from EMI and RFI.

- Uninterrupted Operations: Minimizes data loss, system failures, and communication disruptions.

- Consistent Performance: Ensures precise, interference-free operation of advanced technologies.

By shielding vital components from interference, these enclosures help maintain the integrity and efficiency of modern electronic systems.

Trusted Designs for Maximum Efficiency

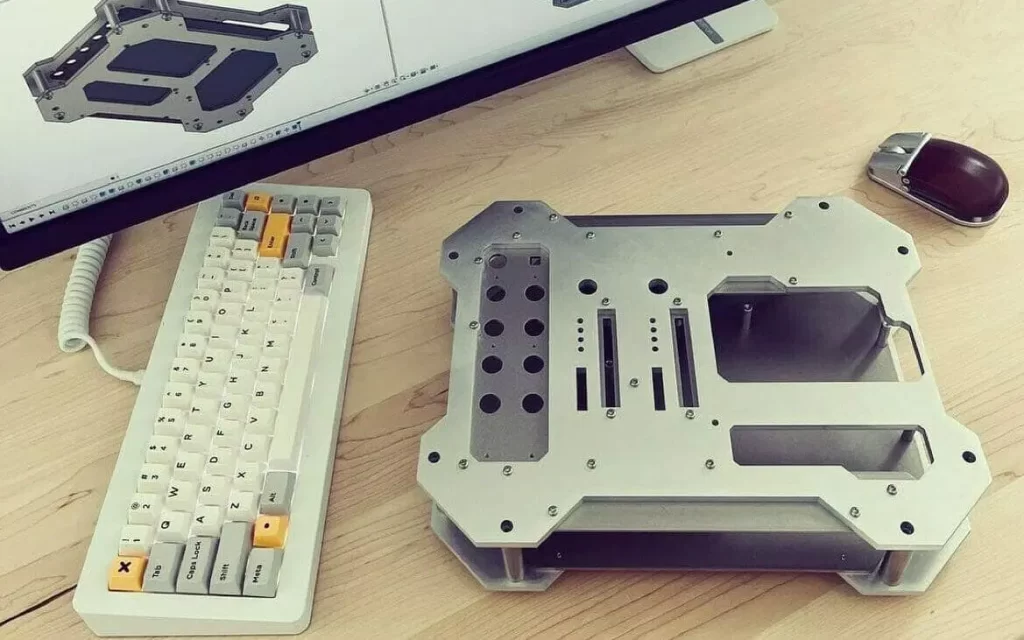

Modern EMI shielded enclosure designs incorporate advanced materials and engineering techniques to deliver robust, long-term protection. They are available in various configurations, ensuring compatibility with a wide range of industries and applications.

- Precision Engineering: Designed to meet exact specifications for high-performance systems.

- Durable Construction: Resistant to temperature variations, humidity, and mechanical stress.

- Flexible Integration: Adaptable to diverse equipment sizes, layouts, and usage conditions.

From compact control units to large industrial systems, these enclosures ensure reliable shielding without compromising design flexibility or accessibility.

Supporting Safe and Stable Environments

EMI shielded enclosures contribute to creating safe, stable environments where electronics and communication systems can operate seamlessly. They protect both equipment and personnel by reducing the risks associated with electromagnetic exposure and system malfunction.

- Safety Assurance: Maintains compliance with global electromagnetic compatibility standards.

- Stable Performance: Prevents interference that could affect mission-critical operations.

- Enhanced Equipment Lifespan: Minimizes the impact of external electromagnetic fields on components.

These enclosures are key to ensuring dependable functionality in healthcare, aerospace, telecommunications, and other precision-driven sectors.

Driving Innovation Through Advanced Shielding Technologies

Continuous innovation in emi shielded enclosure has led to enclosures that are lighter, stronger, and more energy-efficient. The use of innovative materials and sustainable manufacturing processes is shaping a new generation of protective solutions.

- Advanced Materials: Incorporates conductive coatings, composite metals, and high-performance alloys.

- Eco-Conscious Manufacturing: Reduces environmental footprint through efficient production.

- Smart Integration: Supports the growth of connected systems and smart technologies.

These advancements ensure that EMI shielded enclosures remain a cornerstone of modern electronic protection strategies.

Conclusion: Ensuring Reliability in a Connected World

Trusted EMI shielded enclosure designs are essential for maintaining optimal performance in an interconnected environment. By preventing electromagnetic interference, they safeguard the efficiency, reliability, and longevity of sensitive equipment. As technology continues to evolve, investing in high-quality shielding solutions ensures stability, safety, and consistent excellence across all applications empowering industries to operate at their best every day.